Detect, Correct, and Prevent Quality Issues Before They Escalate

Using SynergySPC, our real-time Statistical Process Control (SPC) software, you can reduce scrap and waste, increase profitability, and maintain consistently high standards across your manufacturing floor.

Not sure whether you need SPC? Take this quick self-assessment, download your customized report, and start improving your quality today.

Powerful SPC software, used by teams all around the globe.

Tackle Your Quality Control Business Challenges...Now.

Since 1983, our SPC software has been providing manufacturers the innovative quality control tools they need to tackle some of their most pressing issues. From cost control to process optimization, compliance to production consistency – with Zontec, it’s challenges … solved.

Total Quality Management of Processes

Zontec offers clear insights into the stability and capability of your manufacturing processes, enabling precise, real-time course corrections at any point on the production line for improved efficiency.

- Automate data collection to improve accuracy, efficiency, and consistency in quality control processes

- Easy to use for every member of your team

- Real-time analysis to prevent issues

- Root-cause analysis ensures they don’t happen again

Optimize Efficiency to Increase Profitability

Our SPC software helps control costs and improve your bottom line by minimizing variations and defects in the manufacturing process. By continuously monitoring production data to detect variations before they result in defects, you can:

- Reduce material scrap and waste

- Reduce rework

- Mitigate risk

Boost Brand Reputation

By proactively detecting and preventing defects, Zontec’s SPC software reduces recalls, returns, and negative reviews, protecting your company’s reputation. High-quality products lead to stronger customer loyalty, positive word-of-mouth, and a competitive advantage in the market.

- Increase shareholder value

- Consistent, ongoing compliance

- Increase customer satisfaction

- Attract prospects

A Full Suite of Statistical Process Control Software Solutions

Statistical Process Control (SPC) is a method developed by statisticians that employs highly complex calculations and data analysis to monitor and control the processes involved in manufacturing.

Zontec’s SPC software takes the complexity of quality control and makes it simple.

From shop floor workers to engineers to C-suite executives, every member of your team can easily access and utilize Zontec’s SPC solutions to ensure your manufacturing processes consistently meet design specifications in real time. Zontec offers a range of customizable SPC quality assurance solutions, tailored to fit the unique needs of manufacturers of all sizes.

Ideal for small and mid-size manufacturers, Synergy 1000™ software enables you to utilize real-time SPC data in a standalone or network implementation.

Top Features

- Automatic data collection

- Quick charting

- Real-time monitoring and analysis

- Instant communication to key personnel

- Reporting made easy

- For more security, Synergy 1000+ adds another operator level

Designed for enterprise-wide applications, Synergy 2000 provides companies an instant 360-degree view of real-time SPC data about their business processes.

Top Features

- Automated data collection

- Enterprise-wide monitoring

- Instant email alerts

- Comprehensive across-enterprise reporting

- Stringent access and security controls

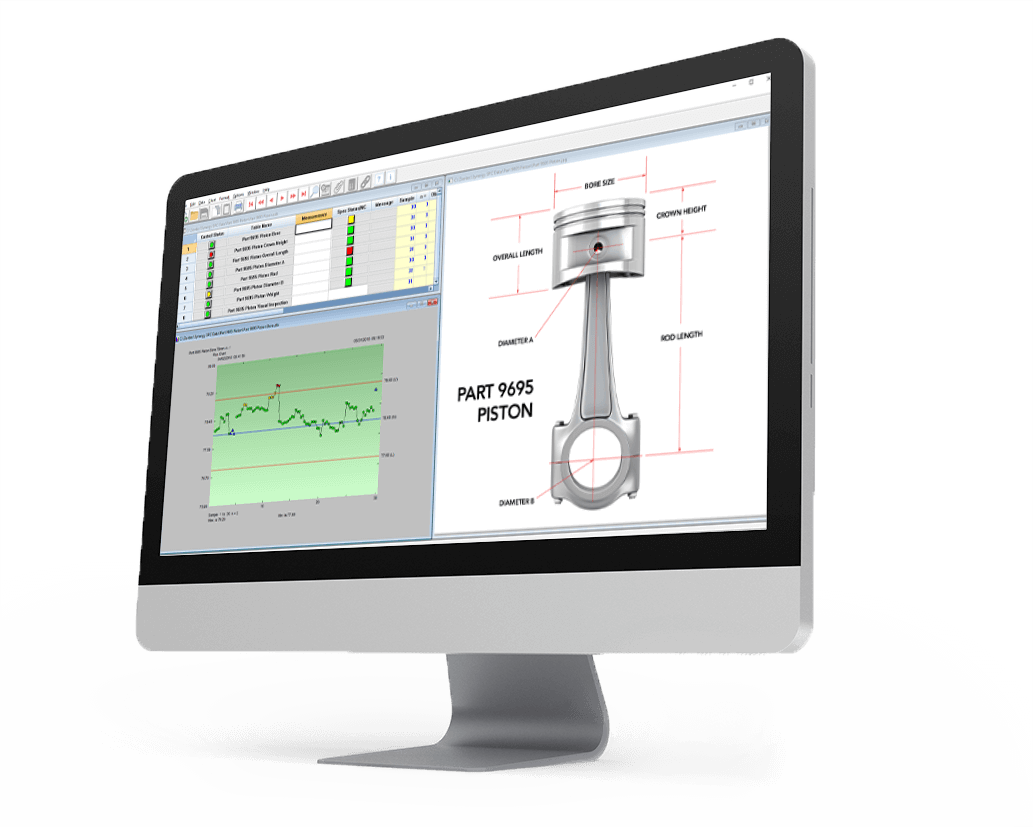

Designed for global manufacturers with global suppliers, Synergy 3000™ provides real-time views of processes across the entire supply chain for centralized, comprehensive quality control.

Top Features

- Wide variety of data analysis tools

- Data collection, charting, monitoring, reporting

- Six Sigma problem solving

- Microsoft SQL® database engine

- Micrsosoft NET™ computing platform for easy integration and universal connectivity

Synergy 100 and 100+ revolutionize the way SPC software is purchased and implemented by providing a subscription-based solution with no contracts.

Top Features

- Purchase, download and install in minutes

- Subscription-based

- Less than $2.00 a day

- No long-term commitments

- Charting, analysis, and reports

Synergy™ 1000/64 Subscription brings all the key features and robust functionality of our Synergy™ 1000 SPC software to a convenient, cost-effective, easy to deploy subscription-based service.

Top Features

- Purchase, download, install within minutes

- Less than $4 a day

- No long-term commitments or contracts

- Rapid set-up and implementation

- Flexible data entry methods

- Easy, one-click navigation

Zontec brings the key features and enterprise-wide functionality of our Synergy™ 2000 SPC software to a convenient, cost-effective, easy to deploy subscription-based service with our new Synergy™ 2000/64 Subscription.

Top Features

- Purchase, download, install within minutes

- Less than $5 a day

- No long-term commitments or contracts

- Enterprise-wide monitoring

- Rapid set-up and implementation for quick ROI

Add-On Options Zontec’s easy-to-use add-ons allow you to seamlessly share data between many platforms for the most complete picture of quality in your manufacturing processes.

Top Features

- Multi-function Toolbox

- Dynamic Link Library

Case Study

Synergy Helps TDK Manage 50% Increase in Production Without Adding Staff

TDK Philippines Corporation is a manufacturer in the Philippines of MR (magnetoresistive) heads for hard disk drives.

50%

Increase in Production

300%

Parameters Increase

“We have recently seen our volume increase significantly, and consequently the number of assembly lines increase by 50%. Because we now use Synergy, our operators can perform multitasking, and we did not need to add additional operators to our assembly lines.”

—— Alvin Hernandez, Sr. Manager for TDK

For Every Industry, Every Role, Every Outcome. Zontec Has the Solution.

Whatever your industry, whatever your role, whatever outcomes you seek, Zontec’s suite of SPC software is here to meet every quality challenge.

Industries

Over 5000 companies in more than 50 countries across a wide range of industries rely on the unmatched SPC expertise of Zontec.

Explore Solutions By Industry

Roles

The benefits of Zontec’s SPC software touch every team in your org chart, from quality assurance to procurement, management to R&D, and more.

Explore Solutions By Role

Outcomes

From sustainability goals to increased ROI, your outcomes get better when you turn to Zontec.

Explore Solutions By Outcome

97%

Customer Satisfaction

< 24

Business Hour Support Response Time

90

Minutes Training Time

The Services. The Support. We're Here For You.

Our expert technical support team is here to guide you through any challenge you’re facing. And with our variety of services and training options, we’ll get your organization to implementation and adoption fast.