How Can You Competitively Manage Your Enterprise Without Real-Time SPC Supplier Data?

Summary:

August 6, 2013 | Articles, Quality Assurance, Resources

In today’s global economy, companies are finding innovative ways to obtain a competitive edge. Manufacturing companies are succeeding by managing their enterprise supply chain from suppliers to customers using real-time SPC data. They also test out if a new product is viable through capability studies performed on their existing equipment.The quality of materials can be monitored in advance from suppliers or other facilities regardless of geographic location. During production, real-time data analysis allows companies to be proactive and prevent defects before they occur. Required documentation, such as shipping transmittals and reports, are provided in real-time to the government, to auditors and to customers.

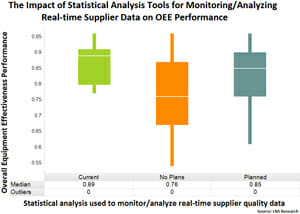

In its 2012-2013 Quality Management Survey, LNS Research found that companies who capture SPC supplier data outperform those that do not. “With a mean Overall Equipment Effectiveness (OEE) of 89% versus 76%, companies leveraging statistical analysis software for acquiring and analyzing supplier quality data in real-time are outperforming those without the capacity. Interestingly, the companies with this capacity not only have a higher OEE rate, these organizations also experience far less variability in performance, with the top 50% of respondents at or above 89% and only dropping as low as 78%.In comparison to the other end of the spectrum, companies without real-time capabilities have far more erraticism in performance.” LNS also found that:

- “Pure-play SPC is providing to be vital for quickly and cost-effectively deploying the solution across the enterprise and through out the the supplier enterprise.”

- “Although many organizations leverage SPC as a quality management tool during the manufacturing process, there are also a number of benefits that can be experienced with its Web-based capabilities to extend statistical analysis tools to external locations such as suppliers and remote, globally distributed facilities.”

- “Improving operational efficiencies , as well as both internal and external quality, SPC can benefit a variety of metrics across the value chain that are instrumental to business performance including first pass yield, cost of quality, on-time and complete shipments , products in compliance, and others.”