Synergy SPC Software Vs. SPC Software

Executive Summary: It has been over 30 years, since SPC methodology was introduced to the US manufacturing industry. At the same time, the personal computer industry was in its infancy. Due to the complex calculations, quality personnel were extremely challenged to apply these statistical methods to their quality functions. In the early 80’s, our first SPC software, SPC TimeSaver, was introduced which was developed on the IBM PC running under the DOS operating system. Today, there are over 30 different SPC software vendors that provide SPC solutions to every industry. The SPC software solutions vary from a single user solution to network solutions, from off-line desktop systems to multiple level on-line real-time systems, from dated technology software to the most cutting-edge advanced technology applications. There are also vendors that provide a suite of products like Synergy SPC software to fit different size of operations and budgets.

May 19, 2022 | Whitepapers | Resources, Whitepapers

Table of Contents

Cutting-Edge vs. Dated Technology

Today, organizations and/or individuals are extremely challenged to find the one SPC software solution that meets their specific needs. For some of the organizations, they have multiple facilities, different sized plants and different product lines with international operations. For some, they have corporate standards for type of platform the software should support, networks, Virtual server, Windows 7, Windows 8, SQL database, .Net, Web platform, internet and VPN connections just name a few. SPC software developed with out-dated technology requires a high degree of maintenance, and consequently is very fragile, unreliable and can cause frequent downtimes. Downtime means losing revenue every minute, and management realizes that it will have an economic impact with financial losses to your organization. If the software is developed with cutting-edge technology on a true Windows platform, you will see the flexibility inherent in Windows applications and keep pace with the high resolution color graphics capability. This older technology is unable to compete with software that is built on a true Windows platform. SPC software developed on old technology struggle with their software development and cannot keep pace with today’s constantly changing technology. Don’t fall victim to out-dated technology instead of cutting-edge technology that can be modified quickly.

To become the best SPC software in the market place, it takes a high degree of commitment and dedication. It requires innovation and listening to customers’ feedback. The software must be easy-to-use, logical and well engineered with an aggressive product development schedule. These software updates add value by consistently being delivered to customers, incorporating new ideas, new suggestions, new innovations and new technologies. It takes years of experience and a high level programming knowledge with engineering expertise to develop the best SPC software system. We have done just that which has resulted in an outstanding Synergy SPC software suite of products to serve every industry world-wide. In contrast, most other SPC software is developed with dated technology, poorly engineered, includes no innovation, developed in piecemeal fashion without a logical design plan, has few updates (which are mostly bug fixes) and imitating others with cosmetic features. Those SPC software vendors give you so many promises and excuses without any true results. While it may be widely believed that “all SPC software products are pretty much alike” true innovation does not come from copying, mimicking or imitating other SPC software. The last thing your company needs is to be encumbered with older technology software that is difficult to implement and learn. Synergy SPC software is regularly updated to incorporate new technologies and the ever-changing needs of our customers.

Apply Correct SPC Methodologies and Rules

Often overlooked, the most critical and important component for SPC software systems is applying correctly the SPC standards, methodologies and rules. Most individuals are unaware of this when they are evaluating SPC software. They must trust that SPC software vendors will incorporate the correct rules into their SPC software. Unfortunately, this has not been the case. SPC methodologies and rules take complex programming and experience, with years of commitment and dedication to develop so that the SPC software performs properly. We know that, because we did it with all of our Synergy SPC products. We have been implementing these SPC standards, methodologies, and rules correctly for 30 years. One of the most wide-spread myths related to SPC software is the automatic calculation of control limits. Control limit calculations are one of the most critical features within the SPC software. In the Synergy SPC software, we do not include the automatic control limit calculation feature when the data is added. For 30 years, we have had many requests to include this feature in the software. We have declined to do so because this is an incorrect application of the SPC methodology and rules. Any SPC software vendor that would tell you otherwise is not adhering to well documented SPC standards, methodology, and rules.Using SPC software that applies SPC methodologies and rules incorrectly results in devastating consequences. In a highly unpredictable and/or unstable production environment, companies lose tremendous amounts of money due to production errors and untold hours lost trying to assign the correct cause to these issues. If critical decision-making is made based on incorrect information, the tangible results are easily felt company-wide and the true causes of errors remain unknown. Loss of trust in the accuracy of your data may result in strained relationships internally and with both customers and suppliers that translates into recalls, audits, penalties, and ultimately business losses.

Real-Time SPC Software

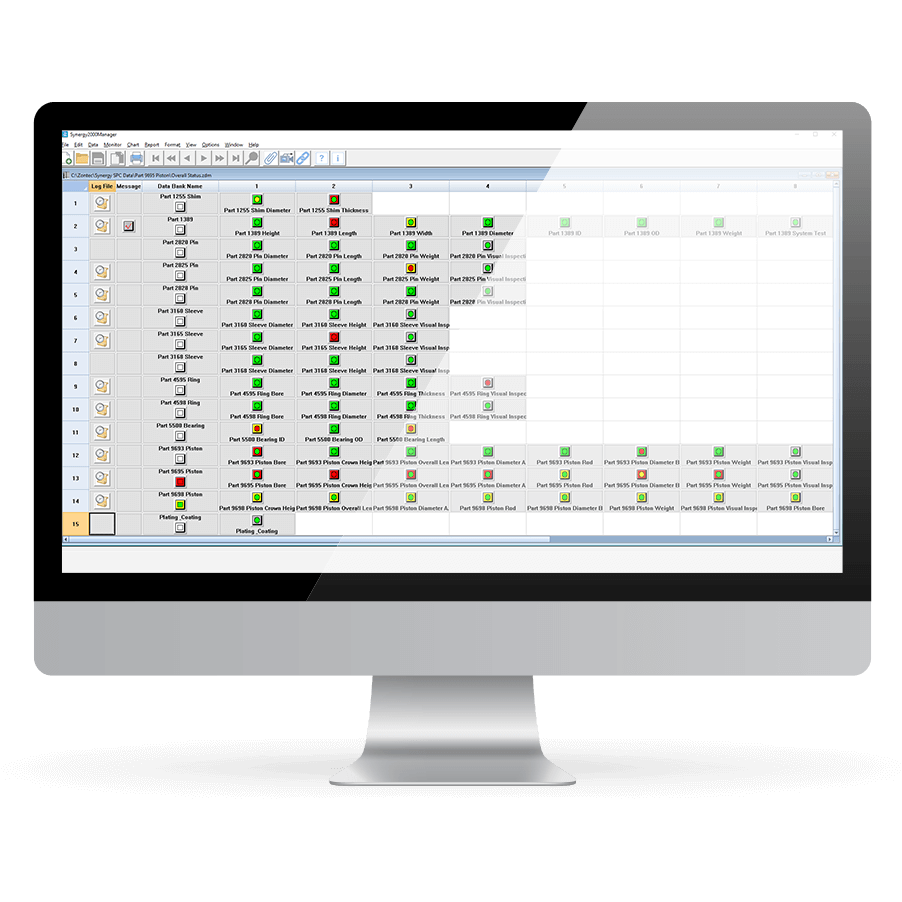

Beginning in the early 80’s, Zontec’s vision for SPC implementations always involved production floor personnel. The production operator is entering data into the SPC software, if the process has out-of-spec and/or out-of-control condition, the system would automatically send a real-time text or email notification to the appropriate personnel to alert them of the process condition. We also believed that data collected during the production process, should be immediately accessible to all levels of the operation including management. Zontec revolutionized the industry by offering the first online “real-time” SPC system with data that is instantly available for all level of users. All our software products have always been built on this real-time foundation.

Cost vs. Long Term Costs

Every SPC software vendor is competing for business by presenting their products as better than their competitors. They are offering you large discounts if you commit to their software. Wow, 80% discount! You can save money for the company, and you are the instant hero by getting such fantastic results with so little upfront investment. Mission Accomplished!

Wait a minute; does any company offer customers such drastic discounts? Perhaps the SPC software vendor escalated their original price to give you a large discount to win the sale. If the vendor is more interested in a quick sale, selling you an out-of-date technology solution versus meeting your long term production goals, is this vendor with whom you want a long-term relationship? Unsuspecting quality personnel may be caught in the trap of vendors whose software is applying SPC methodology and rules incorrectly, the only way to compete with the other SPC vendors is to cut the price for the quick sale. But who will ultimately pay the price? The customer will, with devastating consequences. We all know there is no free lunch. Our Synergy SPC software products are reasonably priced and can truly provide value to your process and assist your improvement efforts now and in the future. Most important of all, our SPC software applies SPC methodology and rules 100% correctly.

Summary

As you can see, there are numerous pitfalls that busy quality managers and production personnel may be trapped into while trying to juggle selecting SPC software while doing their regular jobs. Without detailed and educated information related to current trends in technology, a primer on SPC and how its standards, methodologies and rules must be incorporated into the software, knowledge of true real-time data that results in long term effects, they may be led in the wrong direction. At Zontec, we believe in investing the necessary engineering and development to not only meet your needs today, but also grow with you in the future.

About Zontec

Since 1983, Zontec has been providing statistical process control (SPC) software to industry-leading companies globally. Zontec is highly respected for its innovation and for integrating new technologies to help businesses address quality issues, achieve continuous improvement, and maximize profitability. Zontec is the only company that offers a product suite for all size companies. Committed to an aggressive product development schedule, Zontec software is created, tested, documented and totally supported within the company. This gives Zontec complete control over product development of our products. If a service agreement customer decides to upgrade to the next level of the Zontec product suite they can do so at minimal cost through the 100% Investment Retention program. They will be able to access all their previous data in the new product, minimizing production interruption. Zontec software has been adopted worldwide by more than 5,000 companies, spanning virtually every industrial category. Visit us at www.zontec-spc.com.