Synergy SPC Software Vs. Statistical Software

Executive Summary: In the early 80’s, our first SPC software was introduced and it was developed under the DOS operating system, running on an IBM PC computer. In those early days, there were so many limitations and restrictions on software development due to, minimal computer speeds, memory size, disk space, lower resolution graphic display and the high cost of computers. Slowly, the technology moved from the DOS operating system to 16 bit Windows, 32 bit Windows, 64 bit Windows, .NET platform and now to the Internet. Computer technology has also changed from low resolution to high resolution graphics displays and from slow speed systems to high speed Internet connections. Over the last 30 years, Zontec’s SPC software has advanced from the first generation DOS product, “SPC TimeSaver”, to our most current 4th generation “Synergy SPC software Product Suite”. Since the beginning, we have been committed to offer the best SPC software that is easy-to-use, logical, and well engineered using cutting-edge technology. Today, we have delivered Synergy SPC software products that have fulfilled the goal we set from day one.

May 19, 2022 | Whitepapers | Resources, Whitepapers

Table of Contents

Statistical Software

While we have been delivering the best SPC Software on the market, we have come across at least 10 statistical software packages also on the market, which provide for different kinds of solutions. They are Minitab, Statgraphics, JMP/SAS, SPSS, Statistica and Q-DAS. These statistical software programs incorporate full statistical functions for data analysis, run variances tests, correlation tests, normality tests, linear regression analysis, nonlinear regression analysis, ANOVAs, two-level factorial design of experiments, general factorial design of experiments, Taguchi method design of experiments and multivariate analysis just to name a few. They were primarily developed by college professors associated within mathematical and statistical departments. From colleges and universities like University of North Carolina, Princeton, Penn State University and others. The software has been adopted by colleges as a teaching tool for math, statistics, undergraduate, and graduate students. Most students use it in one or two courses of their college program and never want to see it again.

Most statistical software programs are not designed to be used online in a real-time environment to meet the needs of users on the production floor. They are used for a single desktop computer using historical data for analysis, studies, and reports. It would be extremely difficult to train production and quality personnel to learn and apply SPC methods by using statistical software. Even the quality and production engineers may have a hard time using these high level statistical tools. Statistical software is designed as an off-line application; it will be used by engineers to take the live data collected by the SPC software for off-line analysis and studies.

SPC Software

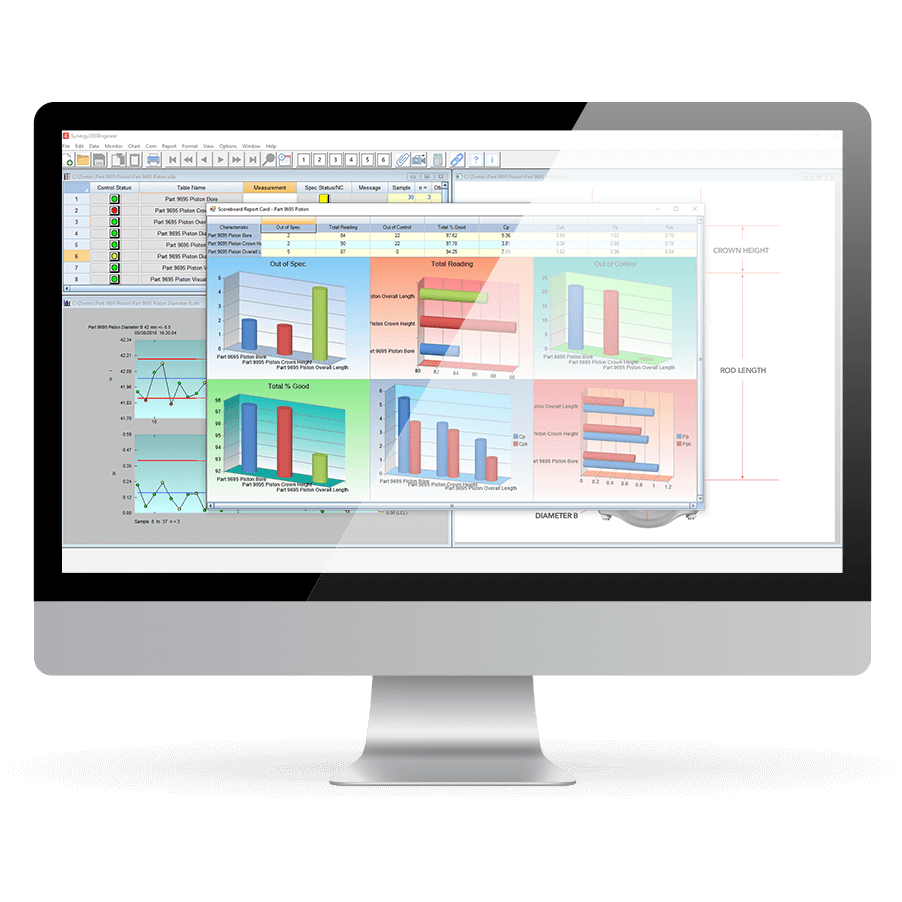

Synergy SPC software, including its methodologies and rules, was introduced for the manufacturing industry to manage their process and operations using simple statistical methods. Utilizing simple statistics functions to improve the production process does not require complex statistics. Synergy SPC software is developed by engineers familiar with the manufacturing process, who understand production environments and requirements. SPC methodology has its own sets of rules that must be applied in the manufacturing process and monitoring on a real-time basis. By combining years of manufacturing experience, SPC knowledge, and applying the many rules of SPC methodology, the software is logical and well-engineered, with production-based functions built in the system. This allows the production and quality personnel to adopt to easy-to-use SPC software for the shop floor and quality labs.

Online Real-Time SPC Software

SPC software must be easy to implement and easy to learn, require very low maintenance, be reliable, and reduce downtimes; it should also be capable of allowing multiple, concurrent users, to utilize the system at the same time, to share data live and monitor the on-line real-time production process. Production operators can input data instantly into a real-time system. For example, if the process has an out-of-spec and/or out-of-control condition, the SPC software will automatically send real-time email notifications to the appropriate personnel to alert them. This online real-time SPC software allows the process information to immediately be accessed by all levels of the application, including management. We know the importance of this because we have seen our customers benefit from online real-time data for years. The real-time capabilities are not applied in the Statistical software because it is not part of the system design which is built for a scholastic environment.

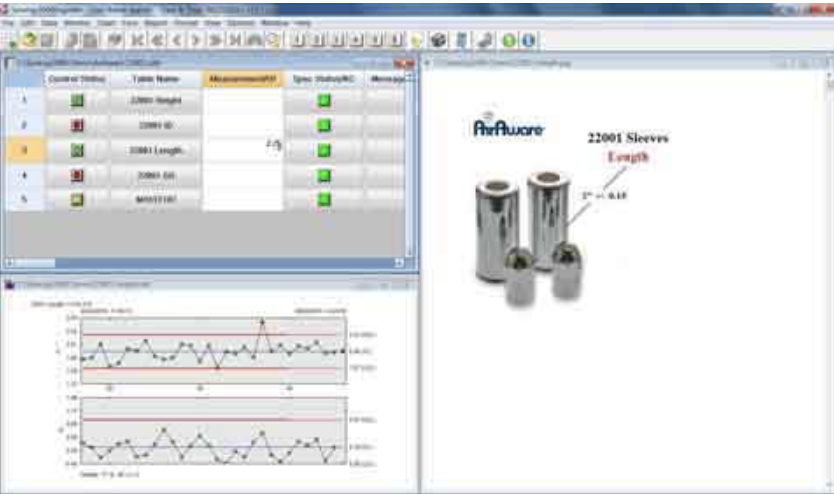

Factory Automation and Device Integration

One element that is also vitally important for SPC software, especially when used in a manufacturing environment, is to integrate with gage devices and data collection equipment. To aid the production operator during data input with an electronic gagging device, SPC software supports various device interfaces to automatically enter data into the software. The SPC software also integrates with data collection equipment to bring the data directly into the SPC software as part of factory automation projects. This feature is developed by the software engineers with many years of manufacturing experiences and automation knowledge. The development teams of Statistical software do not have this expertise or was it created for this environment.

SPC vs. Statistical Software

SPC software and Statistical analysis software are not interchangeable. Both Synergy software and Statistical software complement each other and work well together. Corporate management would find it counterproductive to require its quality and production personnel to use statistical software instead of real-timeSPC software on the production floor. Utilizing inappropriate software will create negative results because it will fail to implement SPC methodologies correctly, resulting in a loss of credibility, confidence and demoralize the team. It is very important to use the appropriate tool for the right application. Allow your quality and production personnel to clearly define the application they need, evaluate the right type of software, set up an implementation plan, train users, measure results, and make it a successful project. Then, if they want to perform additional in-depth statistical analysis, using off-line statistical software, they can use data collected from real-time SPC software. SPC software and Statistical analysis software can clearly complement each other, but do not replace each other.

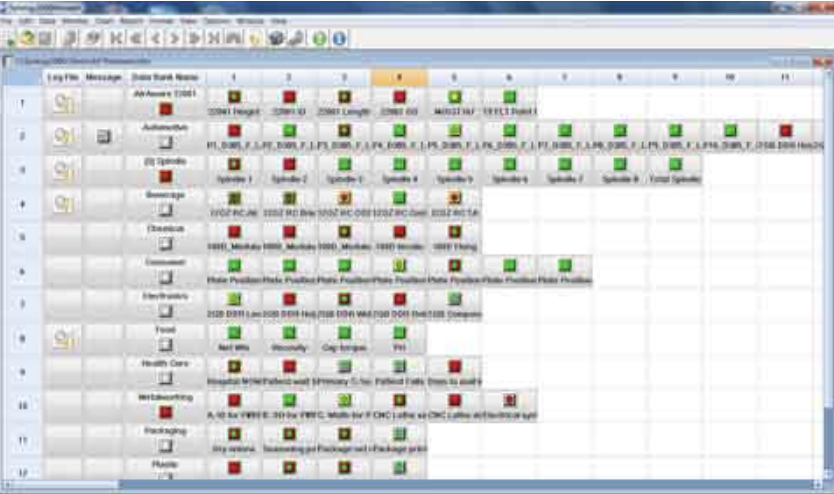

About Zontec

Since 1983, Zontec has been providing statistical process control (SPC) software to industry-leading companies globally. Zontec is highly respected for its innovation and for integrating new technologies to help businesses address quality issues, achieve continuous improvement, and maximize profitability. Only Zontec offers a full suite of products for all size companies. To control the on-going product development process, Synergy software is created, tested, documented and supported totally within the company. Zontec software has been adopted worldwide by more than 5,000 companies, spanning virtually every industrial category. Visit us at www.zontec-spc.com.