How Synergy Software Benefits Your Business

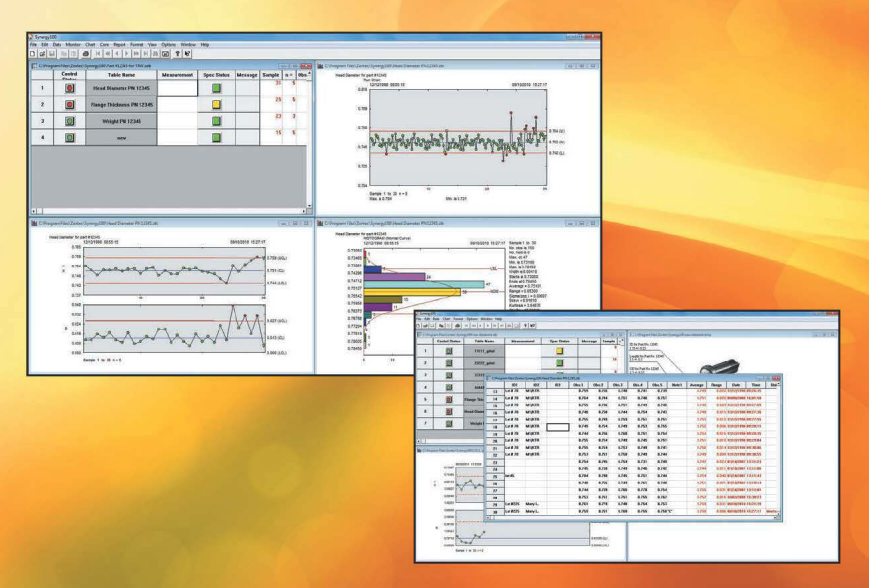

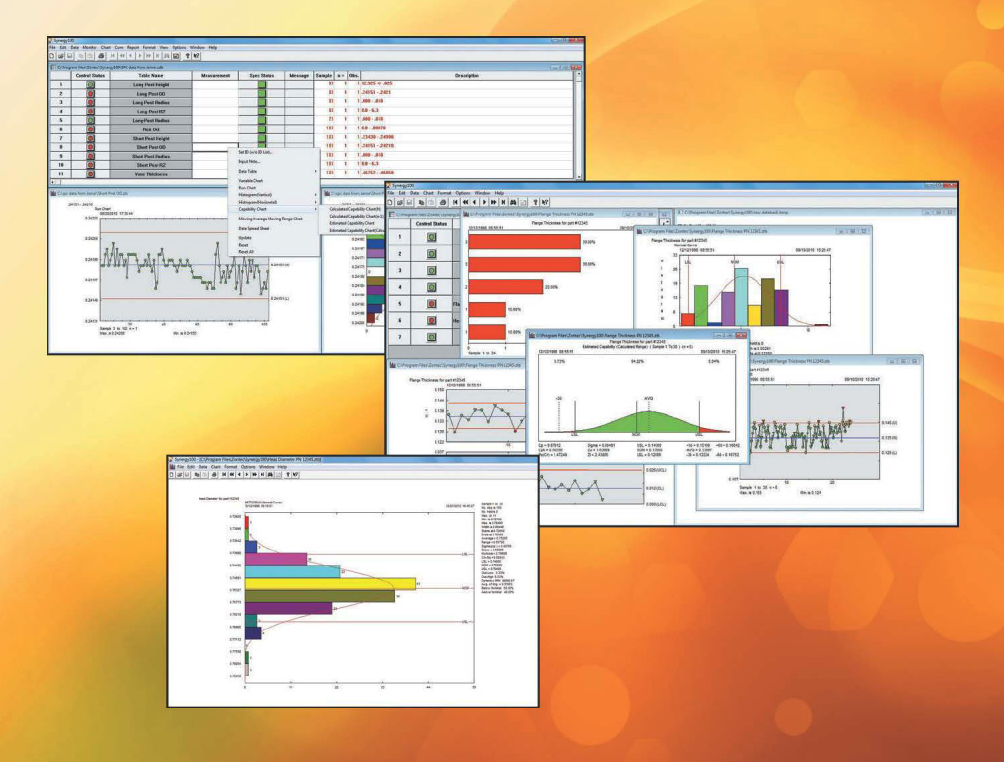

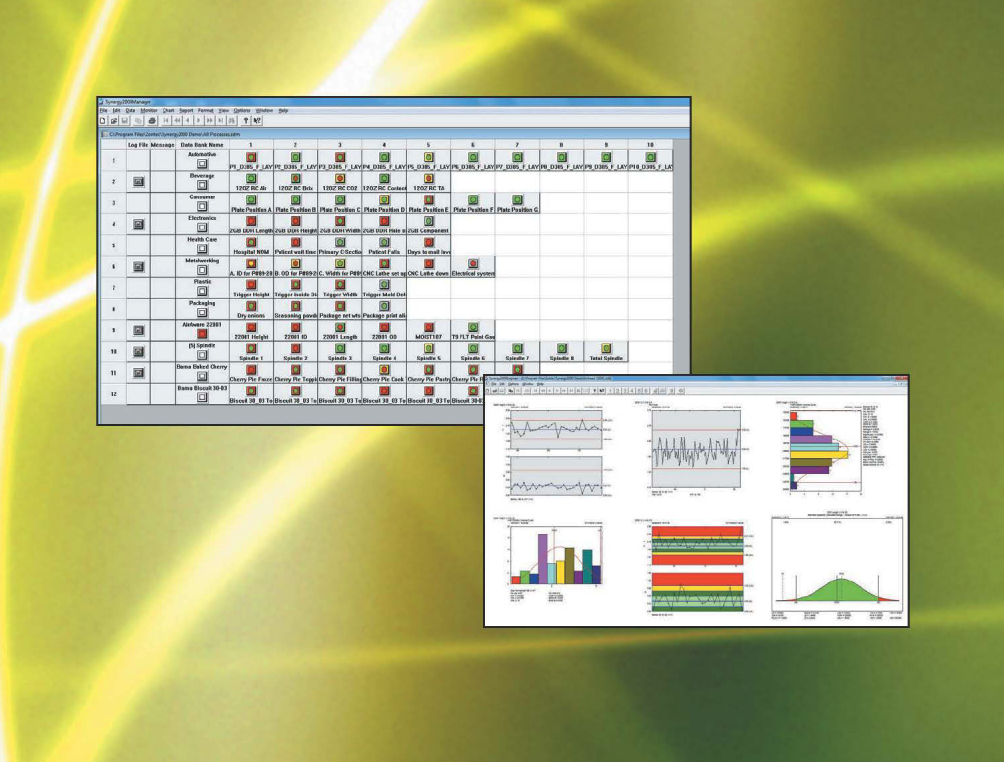

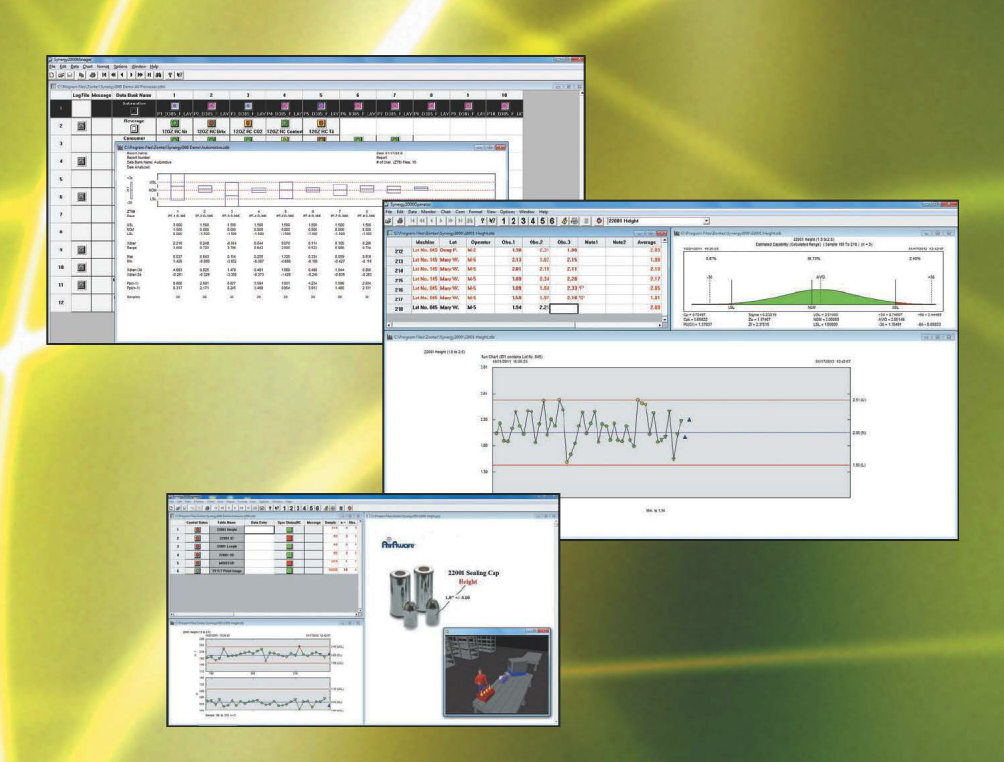

Executive Summary: We are the leader in the industry offering a full suite of Statistical Process Control (SPC) software that meets the needs of companies of all sizes. Regardless if you have one facility or are a global enterprise, with Synergy you can create your database structure, utilize gage connectivity, begin collecting data through multiple collection options, instantly view real-time charts, generate reports, query data samples and take corrective actions to prevent defects. Our Synergy SPC software is designed so that each level of user has their own unique view, access, privileges, charting and reporting capabilities in the system.

April 11, 2022 | Whitepapers | Resources, Whitepapers

Table of Contents

- Realize a Rapid Return on Investment (ROI)

- Seamlessly Integrates Into Your Production Environment

- Delivers Extensive Reporting for All Users

- Meets Unique Regulatory and Customer Requirements

- Reduces Downtime, Scrap Rate and Rework

- Ensures Production of High Quality Products

- Enables Customers to Develop New Products

- Zontec Continuously Innovates Its Product Line

- Zontec Provides Personalized Support

- Zontec’s Track Record Ensures Customers’ Success

“We really appreciate the ability to analyze data while the operator is entering data at another location. The moment the data is in the system, you can graph it immediately. You can chart things in different ways. Synergy has a very user-friendly interface.”

Whitney Ginter, Veridiam Inc.

Realize a Rapid Return on Investment (ROI)

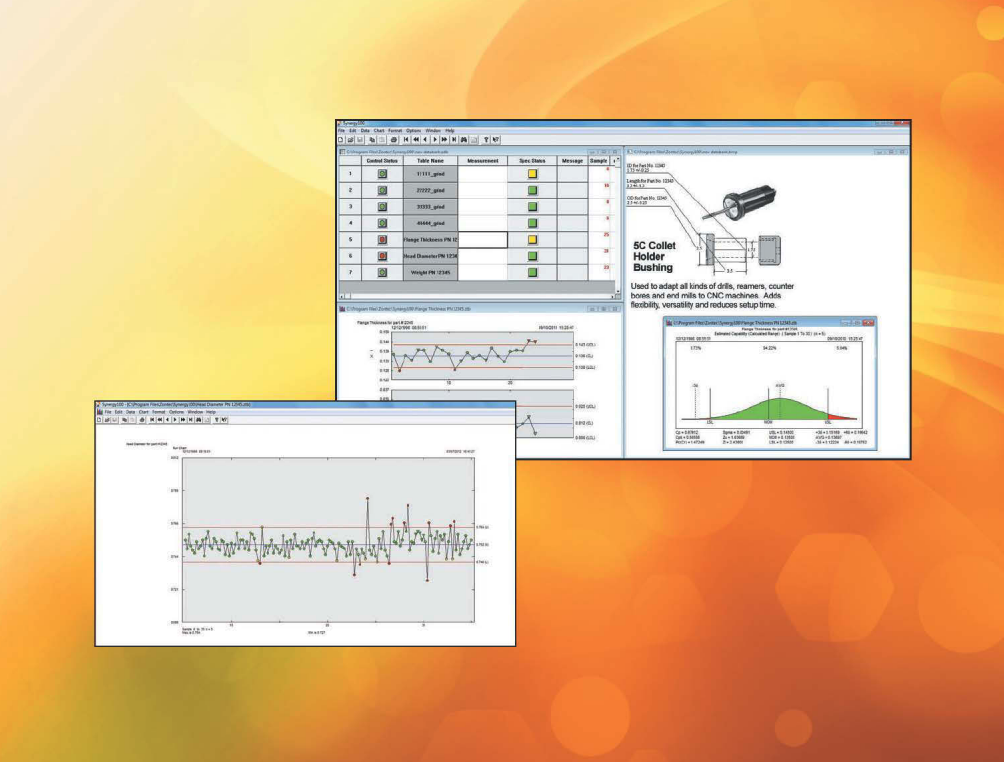

Because the Synergy products are easy-to-setup and train, implementation time is reduced. Customers routinely create Data Banks and Data Tables in minutes to build their database structure. Freed from paperwork, operators can ensure their data is error-free, prevent out-of-control conditions before they occur and focus on their production jobs. Managers can simultaneously monitor multiple processes. Engineers are able to instantly analyze the data, suggest process improvements, prevent out-of-control or out-of-specification conditions, monitor production equipment and provide SPC data and analysis to customers in the specified format.

Once we implemented Synergy,

we immediately saw results. For

us, a process that used to take a

day was reduced to an hour and

½. Synergy easily paid for itself

in a couple of weeks

Bob Hayes, Foam Design

“We selected Synergy because we can input data from multiple devices into the same database. With Synergy, we capture more data about our business. Email alerts for out-of specification products were part of the deciding factor as well.”

Kim Marquis, Polymerics

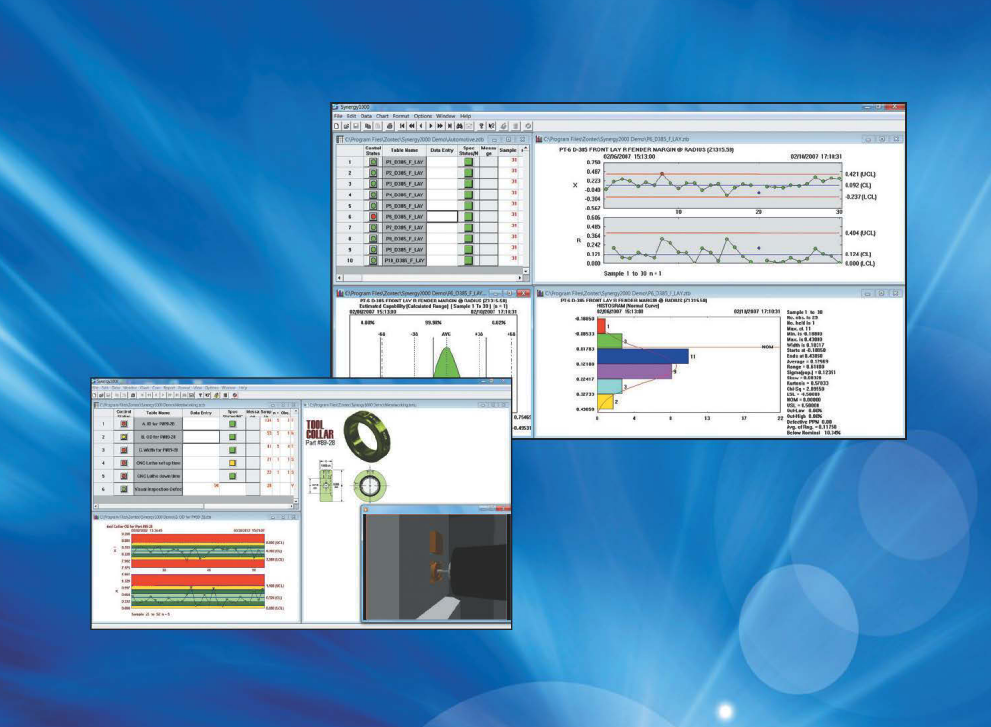

Seamlessly Integrates Into Your Production Environment

Synergy products seamlessly integrate with production systems such as measuring gage devices, optical comparators, Coordinate Measuring Machines (CMMs), Programmable Logic Controllers (PLCs), and Object Linking and Embedding for Process Control (OPC Server). It also integrates with systems like Enterprise Resource Planning (ERP), Laboratory Information Management Systems (LIMs), Supervisory Control and Data Acquisition (SCADA), Manufacturing Execution Systems (MES), or applications like Customer Relationship Management (CRM), Supply Chain, and others in your production environment. All the data stored in Synergy can also be exported to external packages such as Crystal Reports.

“When the Quality Assurance Representatives

(QARs) come to inspect us, I have all the

information they need prepared in packets for

them. Because the data is readily available, we

can provide all the documentation quickly along

with the products we are shipping out.”

Bob Batsche, Carlisle & Finch Co.

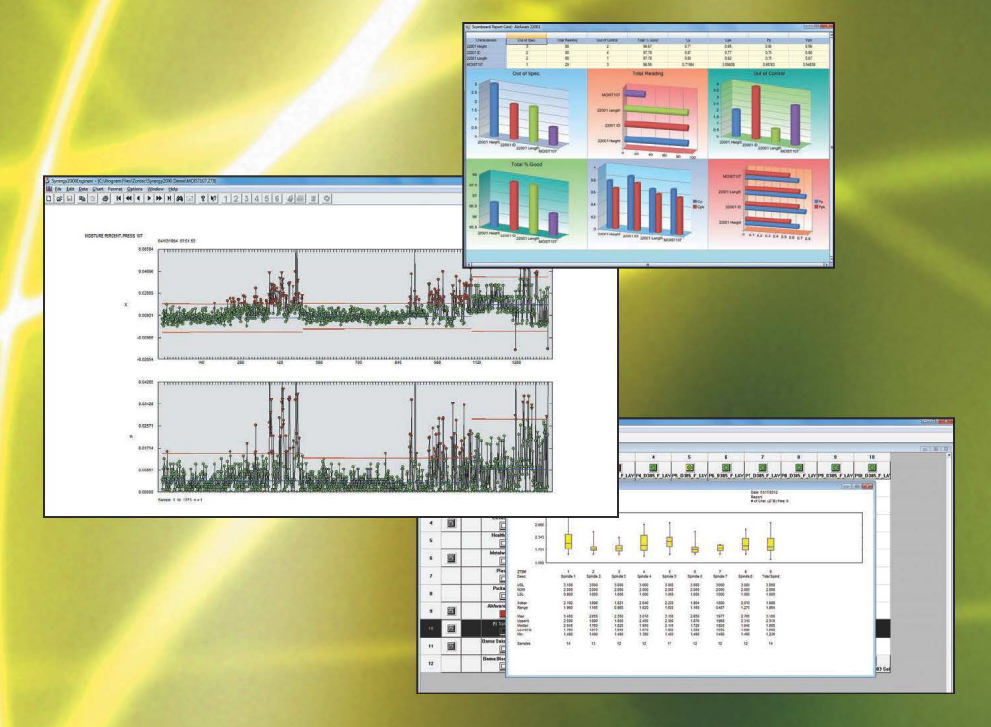

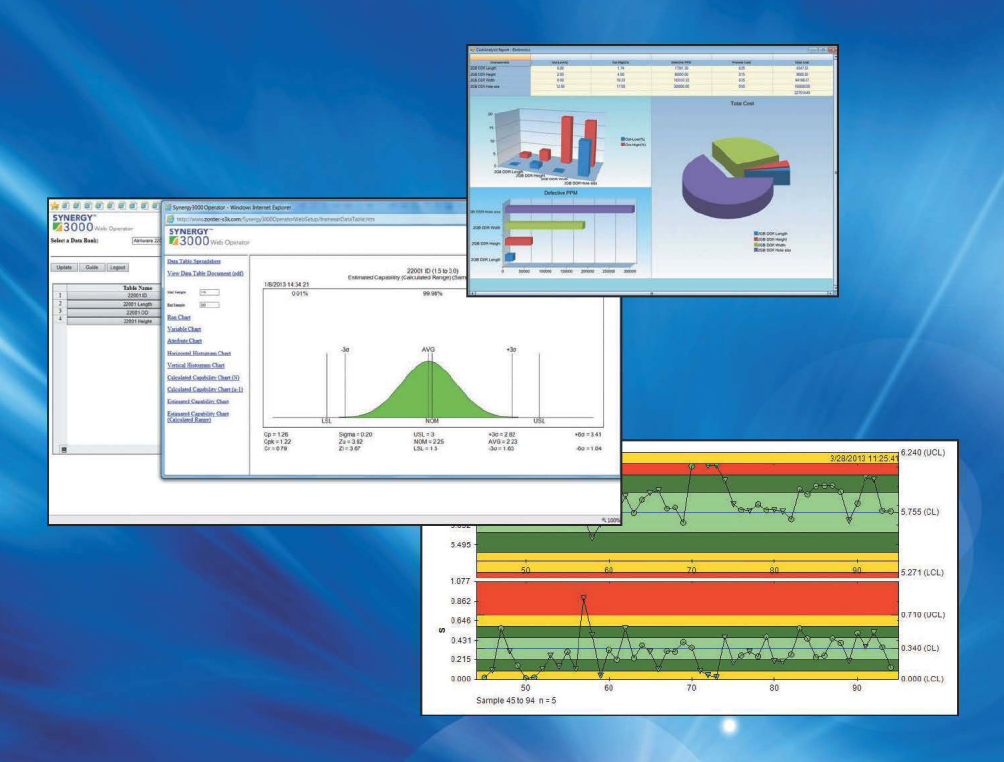

Delivers Extensive Reporting for All Users

Synergy products provide each level of user instant reports about their SPC data. All the reports can be previewed, printed, saved in PDF format or emailed directly within the program. For your managers and engineers, standard reports are customized based upon specified requirements that can include multiple charts on one page. Process Information Reports, Automatic Certificate of Analysis Reports, Scoreboard Report Card Reports and Cost of Analysis Reports provide your managers and engineers with data to compare processes and determine the costs associated with each process.

Meets Unique Regulatory and Customer Requirements

Because all industry requirements are unique, Synergy software contains unique identifiers (IDs) that can be attached to each sample. This provides numerous data querying options that can be used for reporting. Companies regulated by the U.S. Food & Drug Administration (FDA) Title 21 Code of Federal Regulations (CFR) Part 11, use the Synergy software for compliance. Companies from various other industries with exacting regulatory and customer requirements use Synergy software to efficiently maintain compliance.

With Synergy, we have the data we need to meet our Automotive Industry Action Group (AIAG) and customer reporting requirements.

Dan Corrigan, Halla Climate Control Canada

We are able to show our customers in real-time that their product is ‘in control’. We bring every customer

to a SPC station where they can view the data live.

Mike Woznicki, SPIROL International Corporation

Reduces Downtime, Scrap Rate and Rework

Using Synergy software, you have instant data to proactively react when a processis trending towards out-of-control, out-of-control or out-of-specification, even if it is at another facility or at a supplier site. With the software, you can email appropriate personnel if out-of-control or out-of-specification conditions occur. By using Synergy, users prevent defects from occurring, reduce rejects, scrap rates and production downtime. This saves on rework and increases production.

“If the data shows that a particular machine is trending towards being out-of-control, we take corrective action. We have reduced downtime. The Synergy 2000 software has also enabled us to reduce waste. We have reduced our scrap rate by 2%. We are now able to ensure that our production process meets our daily goals and delivers a quality product.

Cary Williams, Amantea Nonwovens LLC

I think where Synergy has helped our company the most has been on final inspections.

Since implementing Synergy we have reduced our rejects by 2/3rds.

Bob Batsche, Carlisle & Finch Co.

Using the data from Synergy and a lot of hard work, we have been able to reduce our PPM (Parts Per Million) from 50 to 10.

Dan Corrigan, Halla Climate Control Canada

Ensures Production of High Quality Products

Synergy customers rely on Synergy to statistically verify that they are consistently increasing product quality while delivering products on-time to their customers. Through this continuous improvement, customers decrease defects and reduce parts inspection.

Using the data from the Synergy software, we can determine if we can produce a new product using current processes before we actually produce it.

Aditya Deshpande, Cumberland Plastics Solutions

“With Synergy, we are able to show customers at their location the exact machine that would be used to produce the new product, what tolerance the machine is currently running and the capability history of that machine. This type of information shows the

customer what they need to see before moving forward. Synergy provides us that edge to win the business.”

Douglas Winfrey, United Gear and Assembly

Enables Customers to Develop New Products

With SPC process capability and production data at your fingertips, you can monitor production equipment and test out new products with your existing equipment. Zontec customers have also used their data to win new business.

Provides a Global View Your Entire Supply Chain

Today, manufacturers use innovative technology such as cloud computing in Synergy to instantly view SPC data from anywhere in their global supply chain, including from supplier locations. With Synergy, you can prevent defects before they occur, make process improvements, verify customer requirements and analyze your business profitability.

Since using Synergy, we have reduced our scrap rate by 20%. We now know where we had waste in our process, realistic values to base our key performance indicators on, and how to improve our margins. We began to use Synergy Web applications with our sister companies in China and Bulgaria as well as with our main suppliers.

Fedele D’Alessandro, LMPsrl

Zontec Continuously Innovates Its Product Line

Highly respected for constantly integrating innovative technologies such as cloud computing into its product line, Zontec maintains an aggressive product development schedule to consistently deliver industry-leading products to its customers. Zontec software is created, tested, documented and totally supported within the company without outsourcing. If a service agreement customer decides to upgrade to the next level of the Zontec product suite, they can do so at minimal cost through our 100% Investment Retention program. They will be able to access all their previous data in the new product, minimizing production interruption.

We selected Synergy because of its usability, because it was cost-effective, and because of Zontec’s 100% Investment Retention program. We also liked the fact that if we decide to upgrade, all our data banks and data tables will roll right into the next generation product.

Brian Brooks, Domestic Fastener & Forge, Inc.

Zontec provides excellent service. I was really surprised how quickly my questions were answered instead of taking days like other service providers. They have extremely quick response time to help with any technical issues we may be experiencing. In dealing with many technical support groups for various software applications that we support within our company, Zontec is definitely one of the best in customer service.

Cristina Martinez, Stanley Black & Decker

Zontec Provides Personalized Support

Zontec recognizes that when you have a SPC software issue, it affects your business. Any delay costs money. Zontec’s technical support team has an extensive background in quality assurance, engineering, computer science and manufacturing to provide you with expert assistance in using the Synergy SPC software, as well as configuring, interfacing and networking your system

“The Zontec product suite was built so that companies of all sizes could use SPC data to improve production. Over the years, we have consistently kept our commitment to continuously improve our product line. We believe that innovative, real-time SPC software empowers our customers to be more competitive in the marketplace.

Warren Ha, Zontec, Inc.

Zontec’s Track Record Ensures Customers’ Success

Since 1983, Zontec has been providing SPC software to industry-leading companies across the globe. Zontec is recognized in the industry for consistently integrating new enhancements and technologies into its product suite. Zontec’s products help businesses address quality issues, strive for long-term continuous improvement and maximize profitability. Zontec software has been adopted worldwide by more than 5,000 companies, spanning virtually every industrial category.