How Synergy SPC Software Improves Your Return-On-Investment

Executive Summary: To meet this increased production, corporations today require a global infrastructure that enables them to view SPC data from remote locations and suppliers in real-time. The Synergy SPC software includes a powerful SQL database as well as Web based applications that enable operators to enter SPC data at their remote locations and manufacturers can instantly access, view and monitor this real-time data.

July 15, 2022 | Whitepapers | Resources, Whitepapers

Table of Contents

Introduction

According to a recent LNS Research and Manufacturing Enterprise Solutions Association (MESA) survey, manufacturers are increasing production:

- 71% of manufacturers are increasing the number of products, Stock-keeping units (SKUs) or variants produced

- 45% of manufacturers striving to shorten the time for new product introduction

- 64% of manufacturers introducing more complex products

- 54% of manufacturers have customers demanding increased traceability documentation

In order to meet these objectives, manufacturers are increasingly looking to Statistical Process Control (SPC) software to help manage suppliers worldwide to streamline their business processes and satisfy customer requirements. With increased visibility into supplier SPC data, companies realize that SPC software can assist them in introducing new, complex products faster and provide customers the increased traceability documents required.

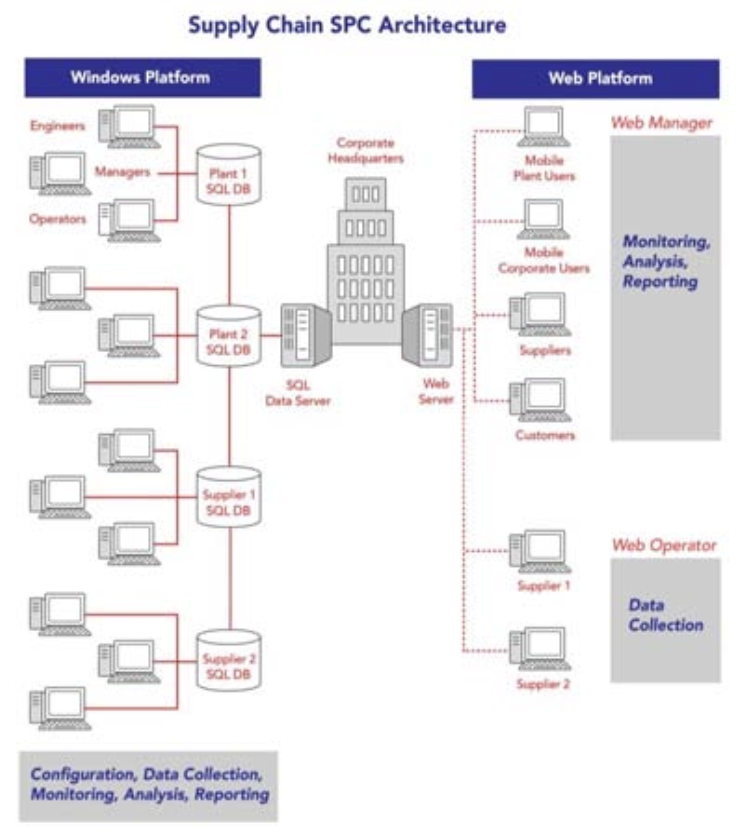

Worldwide Access of SPC Data for Your Enterprise

To meet this increased production, corporations today require a global infrastructure that enables them to view SPC data from remote locations and suppliers in real-time. The Synergy SPC software includes a powerful SQL database as well as Web based applications that enable operators to enter SPC data at their remote locations and manufacturers can instantly access, view and monitor this real-time data. Synergy SPC software utilizes a private cloud computing model that permits personnel anywhere in the world to instantly share real-time SPC data. The manufacturers’ data center maintains central configuration and on-going data management, minimizing supplier IT involvement and freeing suppliers of inconsistencies in data collection, reporting and security. Because the centralized data warehouse serves as host to individual SQL databases for each supplier or specific process, the manufacturer assumes complete responsibility for maintaining and securing supplier data, implementing proper control plans and achieving lot traceability genealogy as defined by design records, contract terms and conditions. "The reason upper management approved the upgrade to the Synergy SPC software was the SQL database and the ability to integrate with other applications easily," said Tim Stutzman of Oregon Freeze Dry.

Manufacturers realize a real-time global view of the SPC data for their entire supply chain. This leads to more informed decision-making, the ability to be proactive vs. reactive to an issue regardless of its location, review historical data to predict future results, instantly generate traceability or audit trail documentation and test-out new products before putting them into production.

Web Applications for Operators

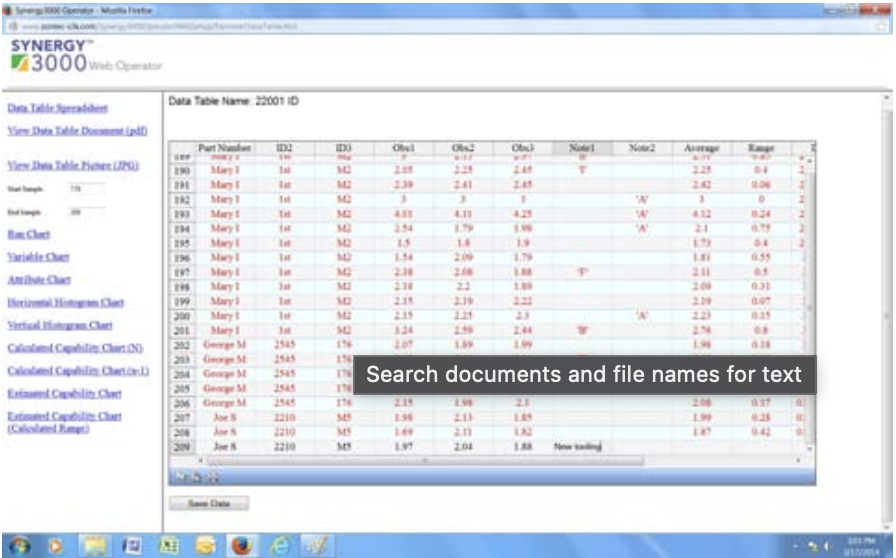

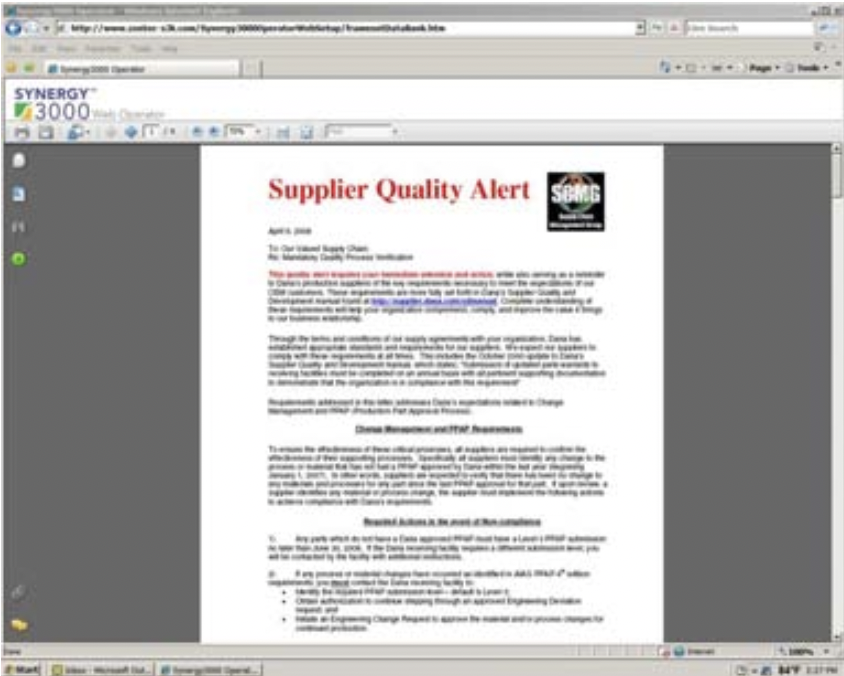

A highly scalable solution, Synergy SPC software provides manufacturers the combination of Windows and Web applications to deliver a consistent, global view of quality data for real-time operational excellence and support for ISO 9001 and TS 16949 international quality standards. Using the Synergy Web Operator, manufacturers can specify requirements to their suppliers for uniform data collection across multiple locations to eliminate data entry errors. Manufacturers can also spot trends and quickly identify quality issues well before these materials are shipped. Documenting causes and corrective actions are incorporated into the data collection process to ensure full accountability during production.

Operators frequently need access to standard operating procedures, engineering drawings, instructional guides, flow diagrams and visual aids during production runs. The Synergy SPC software facilitates ready reference to documents directly within the application, eliminating paper records and version control conflicts because documents are centrally stored and controlled electronically within the manufacturer’s supplier database.

The Web Operator application serves an important dual purpose, benefiting suppliers and manufacturers alike; it provides suppliers with a tool for long-term continuous improvement while allowing manufacturers to manage remote processes.

A Worldwide Troubleshooting Resource for Managers

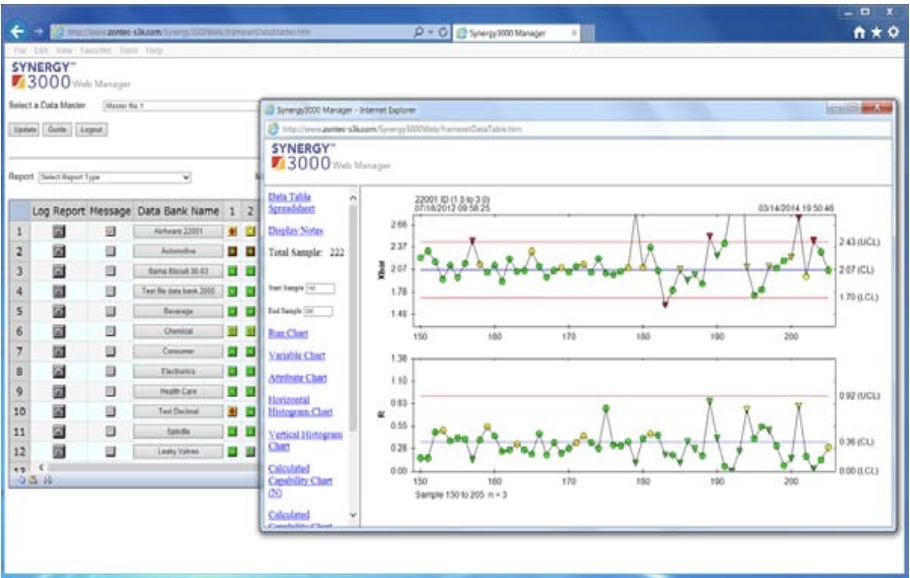

The Synergy Web Manager application is designed for active managers who are often remote, using mobile devices and telecommuters who need to verify process status using only their Internet connection. The Web Manager delivers a “command central” dashboard view of every process condition anywhere in the world. If more detailed information is desired, Web Managers can access the actual data spreadsheets for individual suppliers to examine specific SPC observations, traceability tags or Operator adjustments made during production. A full array of SPC charts and executive reports can be generated in real time. Furthermore, the system can be configured to automatically trigger e-mail alerts and cell phone text messages to designated manufacturer and supplier personnel when out-of-control conditions occur, serving as a worldwide troubleshooting resource.

By taking advantage of this proactive approach, Web Managers can review supplier conformance to requirements before authorizing shipment, prevent the need to quarantine non-conforming products that were inadvertently shipped, or potentially stave off a future product recall due to reliability or safety issues. In many cases, incoming inspections can be reduced or eliminated at the customer site through the many built-in preventive measures in Synergy.

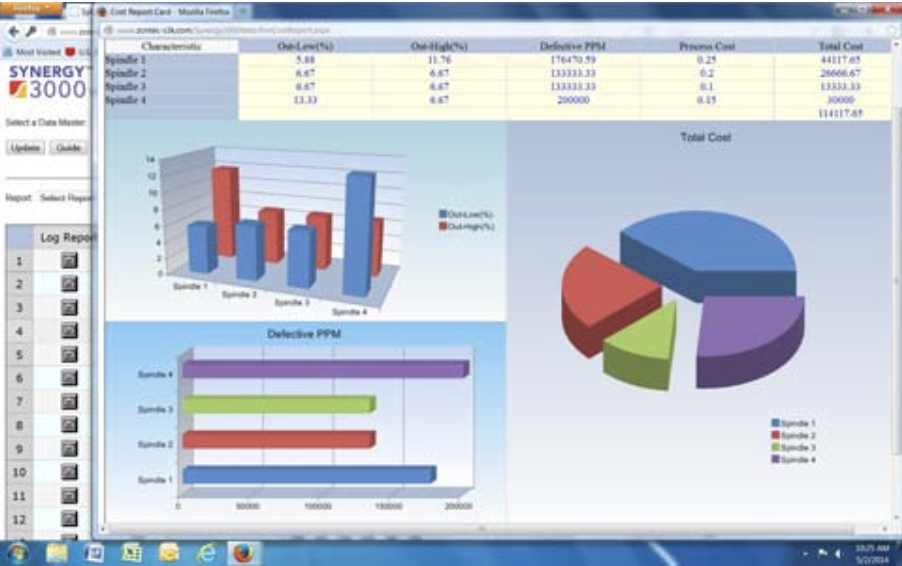

Web Manager Monitoring Dashboard with Chart

Savings Using Real-Time Suppliers SPC Data

As you quickly and efficiently roll out these applications to all your suppliers, you will see tremendous benefits. For example, for each supplier you will save:

- Implementation time

- Reduced travel time and costs related to train and monitor supplier personnel

- Enable supplier operators to prevent errors before they occur

- Allow supplier managers to monitor processes from anywhere

- Empower supplier manager to manage costs

- Gain instant access to supplier SPC data as it is entered

- Notifying supplier of out-of- specification materials before they are shipped to your location

- Eliminate time and cost of supplier resending replacement orders

- Costs incurred by delays to customer

Web Manager Cost of Analysis Chart

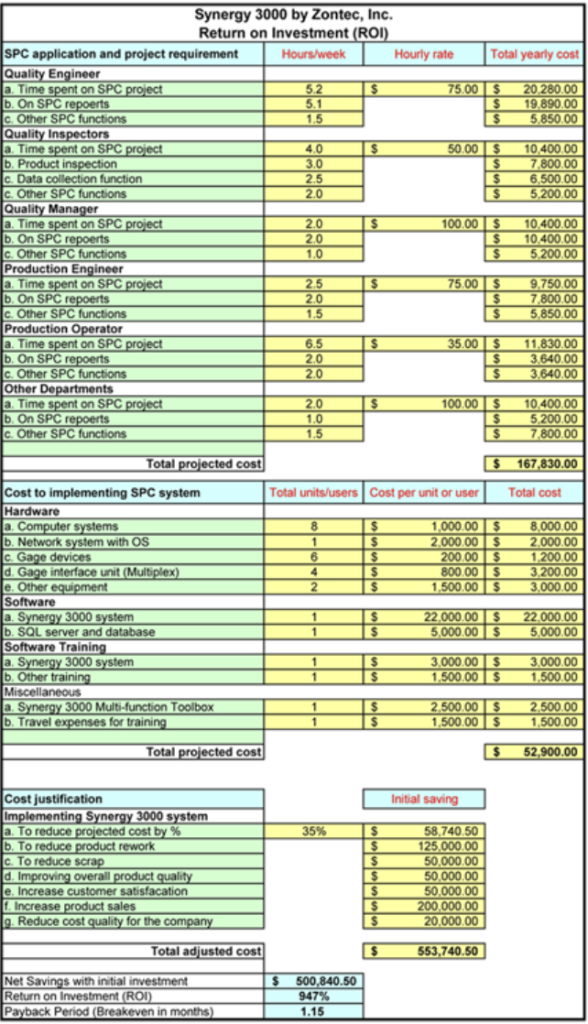

Return-On Investment (ROI) Template

Zontec can provide you with a ROI template where you can calculate your savings based on your internal resources dedicated to supplier issues as it relates to your production process as well. Here are a several savings and benefits you will realize to validate your ROI:

- Reduced time spent on incoming inspections

- Eliminate delays in production due to out-of-specification materials

- Decrease personnel time spent dealing with supplier issues

- Reduce scrap, rework and product recalls

- Shorten on-the-spot conformance to requirements and quality prior to shipment

- Quicker introduction of new products

- Faster time-to-market for complex products

- Comprehensive data for customer traceability documentation

- Worldwide view of your entire supply chain in real-time

- Permanently retain all of suppliers data

“In 2012, we began to use the Web Operator and the Web Manager applications with our sister companies in China and Bulgaria as well as with our main suppliers, “said Fedele D’Alessandro of LMPsrl. “Since using Synergy SPC software, we have reduced our scrap rate by 20%. We now know where we had waste in our process, realistic values to base our key performance indicators on, and how to improve our margins.”

Summary

To flourish in this highly competitive marketplace, businesses must focus their quality efforts on process collaboration and cooperation with suppliers to meet customers’ increasingly demanding requirements. Synergy SPC software provides a rapid ROI by providing manufacturers SPC supplier data before it is shipped to their shop floor. "Eventually, we were able to show our suppliers they could save money and improve their process with the data we collected. Once our suppliers were onboard, their processes steadily improved. Because we are saving our suppliers time and money by reducing rejected products, we have found that they have become our advocates in the process," said Dan Heimann of MASS Precision. The Synergy SPC software is a reasonably small to moderate investment that satisfies the urgent challenges you are facing from customers. Synergy SPC software helps you sustain continuous process improvement throughout your entire supply gaining manufacturers competitive advantage. For suppliers, they benefit from no software maintenance, operators and managers enter and monitor SPC data from anywhere on the Internet.

Manufacturers realize a rapid implementation, tremendous savings with regards to production downtime, reduced scrap, reduced rework, reduced travel for supplier training and inspections as well as more efficiently introduce new, complex products to the market. Utilizing the Web applications for its suppliers, manufacturers can realistically expect a ROI over 900% and payback in a month’s time.