This eBook, The Book of SPC, is a must-read for anyone looking to improve quality control, reduce waste, and enhance manufacturing efficiency using Statistical Process Control (SPC). It provides a clear and practical guide to SPC principles, realworld applications, and how companies can leverage SPC software to achieve higher product quality and process stability. Whether… Continue reading The Book of Statistical Process Control (PDF)

Category: Resources

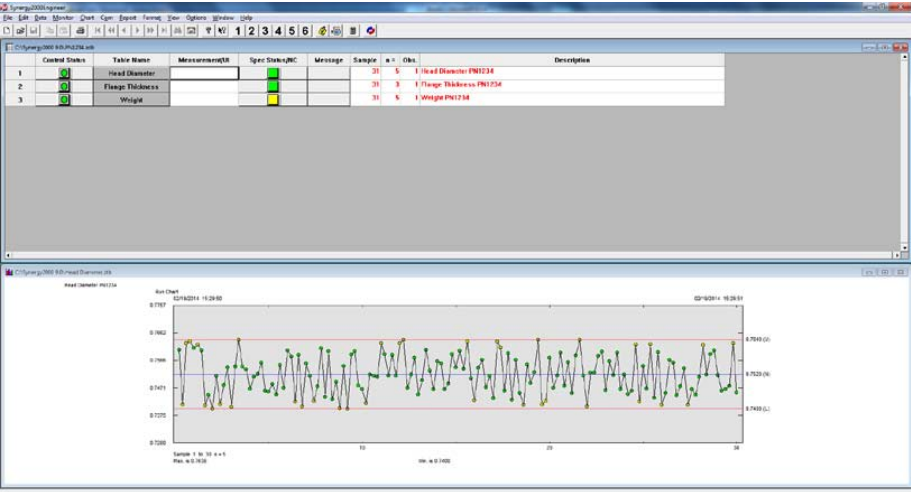

The Ease of Synergy SPC Software Setup Provides Rapid Implementation

Synergy SPC Software Setup and Implementation Software Install (Estimated time: 15-20 min.)With Synergy SPC software you have the option to install on a server or locally on workstations. If the software is installed on the server, just simply create a shortcut to the applicable exe file(s). No clientinstall is required. Since the software is a… Continue reading The Ease of Synergy SPC Software Setup Provides Rapid Implementation

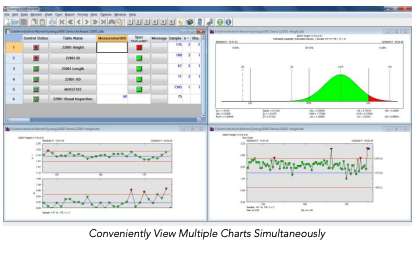

How Synergy Software Benefits Your Business

“We really appreciate the ability to analyze data while the operator is entering data at another location. The moment the data is in the system, you can graph it immediately. You can chart things in different ways. Synergy has a very user-friendly interface.” Whitney Ginter, Veridiam Inc. Realize a Rapid Return on Investment (ROI) Because… Continue reading How Synergy Software Benefits Your Business

Why SynergySPC from Zontec?

Imagine what you can accomplish with the right SPC software As a senior leader, we recognize your commitment to exceptional customer satisfaction, continually improving return on investment and business growth. Together, we share a common interest – quality. By listening to our customers’ quality reporting requirements, we clearly understand the role that real-time data has… Continue reading Why SynergySPC from Zontec?

Why SPC Software Matters

SPC Experience Matters Zontec began and has continued to work with customers in live production environments to develop SPC software that not only meets their customers’ needs but also serves as a competitive advantage. We have a proven history and track record that our methodologies and rules are correct. Fundamental to our philosophy is that… Continue reading Why SPC Software Matters

What is Zontec 5G?

Looking at product history highlights the Zontec innovation and vision as they incorporate the latest technology into SynergySPC software. That is only half of the story. The other half is the robust code used in the development of the SynergySPC product suite. Taking great effort to develop real-time visibility and insights that identify variation in… Continue reading What is Zontec 5G?

Easy Integration With Statistical Process Control Software

What Software Will Automate With SynergySPC, Statistical Process Control Software? The Zontec SynergySPC software suite is robust and flexible allowing it to automate SPC data collection with enterprise resource planning (ERP), Manufacturing Execution System (MES), CMM, PLC, Vision System and many other platforms.Selecting the easiest integration and best statistical process control (SPC) software package is… Continue reading Easy Integration With Statistical Process Control Software

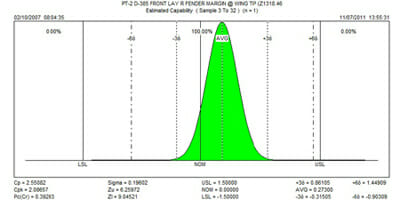

Why Do We Need Statistics Anyway? Capable and Stable Processes

Why statistics? Because they are possibly the most useful tool we have to understand what might happen. Statistics make it possible for us to make fairly accurate predictions with small groups of data. It is not possible to predict individual events but statistics will give insight to the overall results. But let’s dig deeper on why do… Continue reading Why Do We Need Statistics Anyway? Capable and Stable Processes

Upgrading Quality Data Collection

Integrating Technology For Quality Accuracy and Analytics Factories and people are constantly being integrated, especially in the area of quality data collection. Technology is providing new ways to communicate with each other for a broader, more accurate and analytical view of what is happening on the shop floor. It is changing tasks that used to… Continue reading Upgrading Quality Data Collection

Reduce Scrap, Rework, and Downtime with SPC Software

Reduce Scrap, Rework, and Downtime with SPC Software In today’s competitive landscape, you need to leverage every quality management tool possible to help you gain and maintain an industry-leading edge. This is where statistical process control (SPC) software can empower your company to continually improve your processes to reduce scrap, rework, and downtime. You can… Continue reading Reduce Scrap, Rework, and Downtime with SPC Software